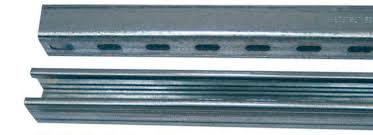

The Installation and Maintenance Of Steel Slotted Channels

A steel slotted channel is used to support structural loads such as pipes, electrical cables, ventilation and air-conditioning units. Slotted channels are quick and easy to assemble and provide a strong framework for all types of mechanical, electrical and plumbing systems. In this guide, we will look at the installation and maintenance of slotted channels.

What Is a Slotted Channel Made From?

A good starting point is to understand what materials are used to make a slotted channel. A slotted channel is usually made from sheet steel with a zinc coating. It can also be made from stainless steel when rusting may be an issue in outdoor use or when it’s used to support corrosive material. Aluminium alloy is used when the slotted strut is used to support something with a lot of weight, and it can also be made out of fibre glass in very corrosive environments.

How to Install a Steel Slotted Channel

Metal struts have slotted channels to allow them to be fastened together and to be secured to underlying building structures. Specially designed sockets are needed to tighten nuts and bolts to the struts. The main advantage of using slotted channels is that it’s easy and quick to connect lengths together using specialised fasteners and bolts. It can be assembled rapidly with only a few tools, reducing building costs in many cases. There is no need for drilling or welding when installing slotted channel struts, and you are only limited by your imagination. Having a hacksaw to hand is advisable when it comes to cutting the correct length of the strut.

How to Maintain Slotted Channel Struts

Maintaining a steel slotted channel is important to ensure the structural integrity of the strut system. It is advisable to replace any metal struts that are showing signs of corrosion or weakness. There are a number of things to look out for and consider when maintaining a slotted channel.

All metal surfaces suffer from corrosion of some sort. The amount of corrosion and the speed at which the steel is affected will depend on the properties of the metal and the environment it is placed in.

Atmospheric Corrosion

This occurs when metal and steel is exposed to airborne liquids, gases or solids. Moisture, salt, dirt and acid can all cause corrosion and are commonly found outdoors.

Chemical Corrosion

If the strut is supporting a structure that contains a corrosive solution, then damage can occur. Chemical concentration level, duration of contact between chemical and metal and temperature all affect the rate at which corrosion occurs.

Storage Corrosion

The entrapment of moisture between surfaces closely packed together creates wet storage stain (white rust). This is normally not an issue but should be removed if found.

Galvanic Corrosion

When two different metals are in contact with one another in the presence of electrolytes, then corrosion can occur. The wetter the atmosphere the strut is placed in, the more chance there is of this form of corrosion occurring.