From the day of inception, industrial world is being introduced to several ground-breaking tools and equipment that has marked major turning point in the niche and, almost every industrial sector somehow get influenced by the innovations. The introduction of FRP reinforced materials is one of such incidents that are resolving a number of issues of several industries. FRP equipment came into use to mitigate the problems regarding corrosion in highly corrosive environments. When proper resin is used and the manufactured equipment is designed and developed properly users can expect maintenance-free long service life.

Advantages of Using Cable Tray made out of Fibreglass

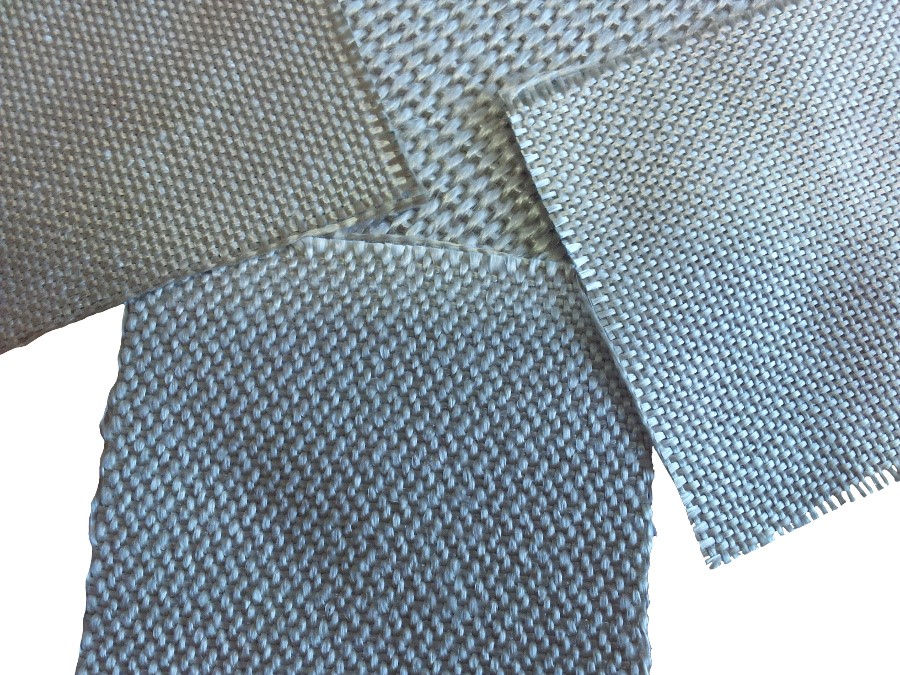

In various applications stainless steel and carbon steel can’t withstand the harsh impact of corrosive environments and with this the advantages of using FRP products are more clearly manifested. FRP equipment like fibreglass cable tray is considered as a more viable option while selecting construction materials.

- FRP composite trays are not vulnerable to expansion even when come under extreme pressure and heat. FRP has an innate resistance to such occurrences and the cable tray doesn’t need any special engineering or additional expenditure to attain such features.

- It comes with outstanding longevity, and can retain the same old look even after many years of installation.

- They are strong and durable in nature but lightweight thus they are easy to access and install.

- When procured from trusted source the users can stay away from the concern of replacement or maintenance at a regular interval. When you obtain the material from well-known organization, it comes with added advantages like UV veil that protects the cable tray from the impact of UV rays even when exposed to the sun for excessively large time.

- The product doesn’t deform in structure even when come under superfluous weight. It can be implemented in any hazardous environment and can be cut and drilled prior to install with normal hand tools.

- Owing to their zero to little conductive nature there is no need of earthing.

- As they have inbuilt anticorrosive nature thus no painting, additional coating is needed.

Aside of cable trays other sectors where FRP material can be used are cooling tower, stair nosing, access ladder, capping, rung covers, storage tank and many more. The cable trays and other structural profiles are installed with bolts and nuts, among the other variety of materials fibreglass bolts are regarded to be the most feasible option to several industries. The obvious reason is the robust structural integrity of fibreglass. Moreover, they are bad conductor of electricity and heat and amongst the other advantages, its highly retardant feature to flame and fire are taken into account while selecting bolts and nuts for industrial use. When budget is in your mind, you will be relieved to know they are indeed the most cost-effective option owing to long service life and zero maintenance cost.