Different Types Of Diaphragm Pumps And Their Uses

It is very evident to understand the mechanism of machinery to operate them without hassles. If you understand the principles of the functioning of machines, it becomes easier to maintain them and ensure their long life. Since maintenance plays a key role in the smooth operation of every mechanical device, it is good for you to know the basics of the mechanism. Every machine runs on a unique principle. You do not have to be a professional to understand the basic technology of the machinery. Take the help of a user manual or the internet to acquire the comprehensive understanding to learn the principles of operation.

Know the Basics

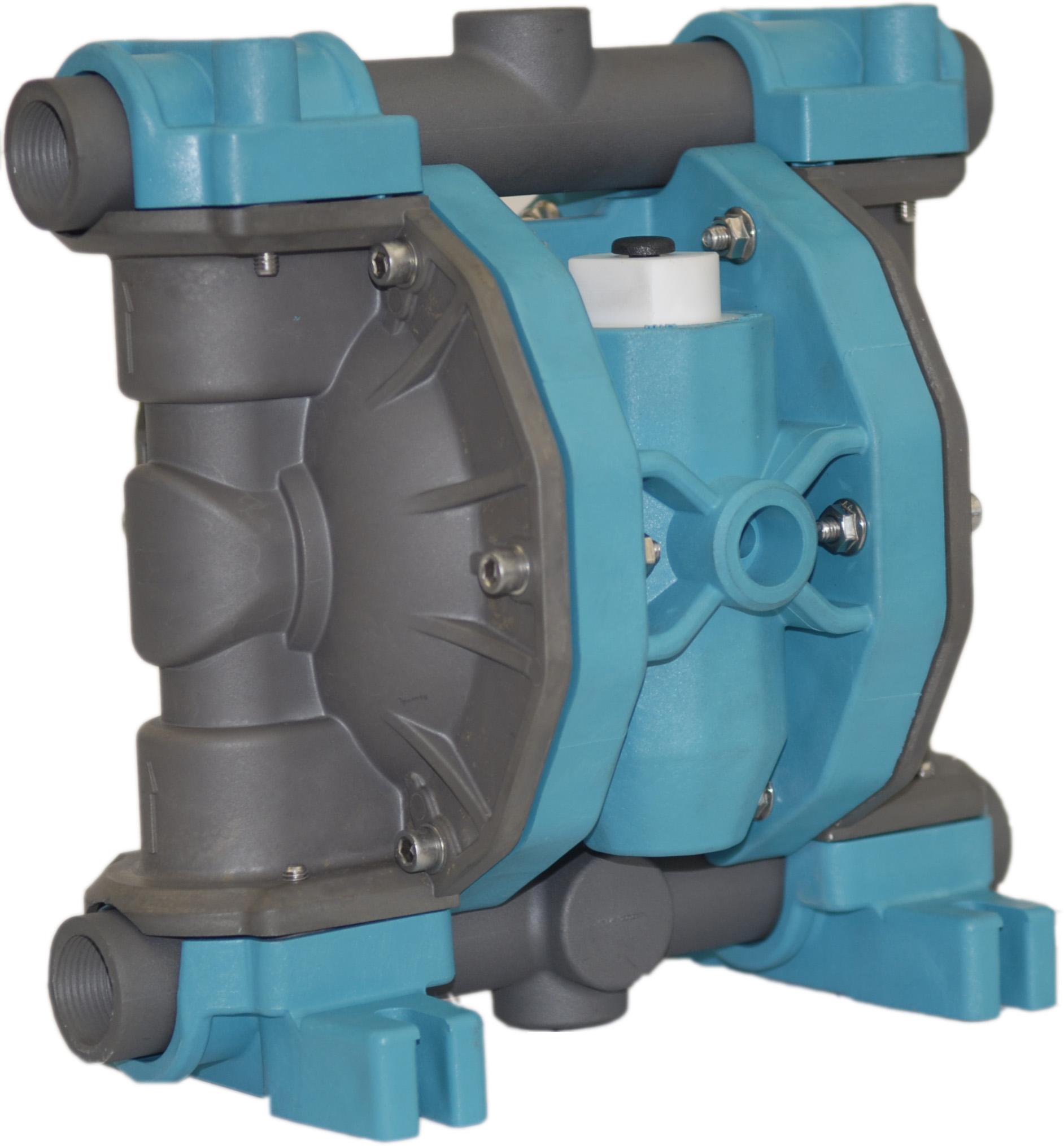

There are different names by which Diaphragm pumps are known. It is also called membrane pump; air operated double diaphragm pump and pneumatic diaphragm pump. It uses the concept of positive displacement to pump a fluid using a combination of reciprocating action of thermoplastic and valves. There are three main kinds of the mechanism. Those with sealed diaphragms with one side in the liquid to be pumped, those using volumetric positive displacement and pumps using one or more unsealed diaphragms. When the volume of the chamber increases, the pressure decreases. The mechanism used in this device is quite similar to an internal combustion engine.

Characteristics of Operation

There are certain beneficial characteristics of Diaphragm pumps that are useful for the manufacturing of many products f high utility. One of the greatest utility of this device is that it is used in the production of artificial hearts. Artificial hearts are a lifesaving equipment for people suffering from cardiac ailments. Their mechanism is also used in making oxygen pumps for small aquariums. These pumps are capable of suction of very highly viscous fluids such as a slurry of snow and mud. These pumps, also available in air operated versions that can resist the effects of even corrosive liquids like sludge that have an amount of solid content.

Availability and Other Use

Some compact pumps are also used as air compressors and as a source of low-grade vacuum. This kind of air compressors is relatively cheaper and less noisy. Moreover, these compressors can be used without adding lubricants. You can get different versions of these machines from stores selling mechanical devices. If you face troubles with the functioning of these pumps, you can take them to an efficient mechanic for repairing. However, if you have precise knowledge about their mechanism, you can fix it by carefully following the instruction given on the internet using the diagrams and videos.